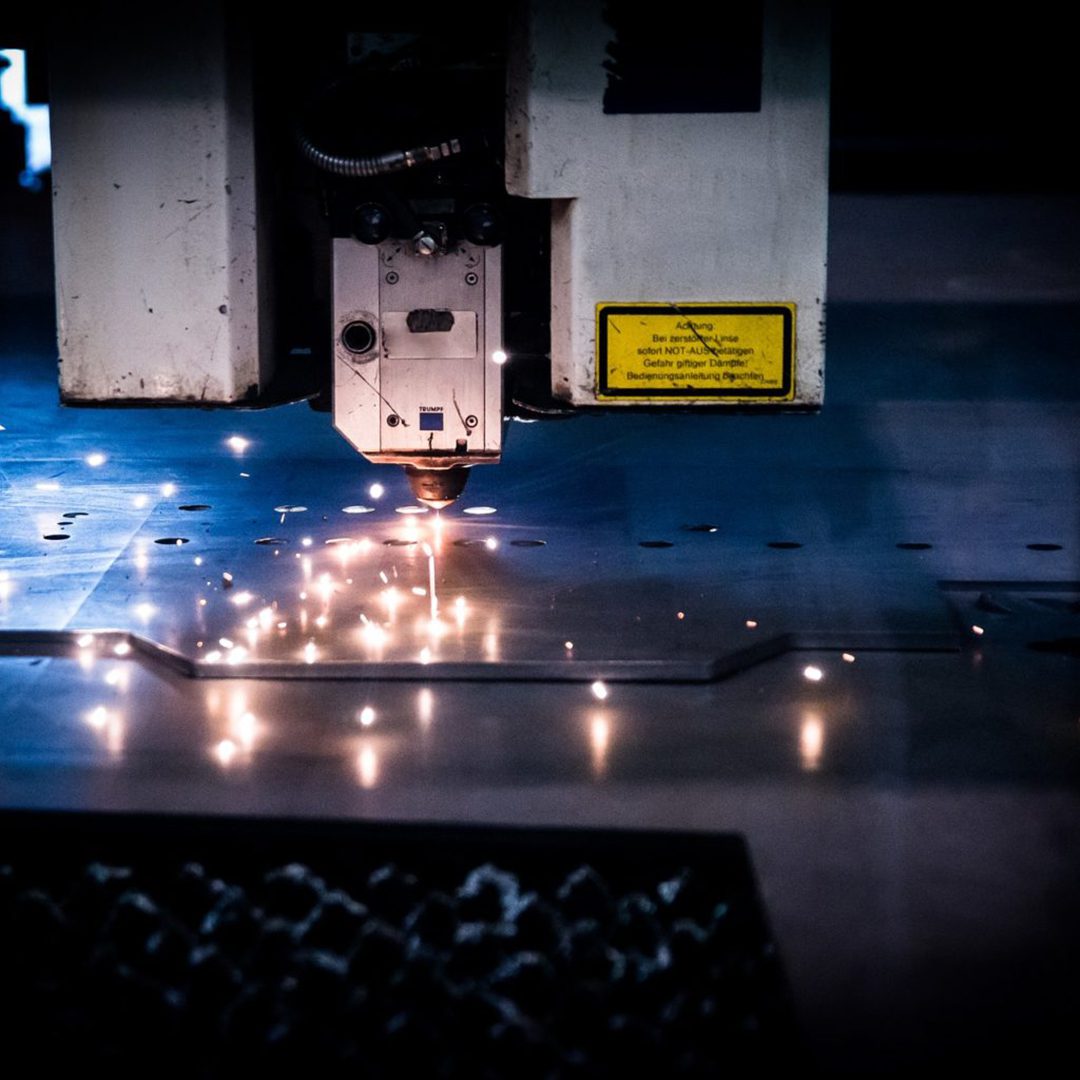

Plasma Cutting vs Laser Cutting

In our last blog post, we discussed some of the myths and advantages of laser cutting. In today’s post we’ll explore how laser cutting differs from plasma cutting. At Arizona Iron Supply in Phoenix, we are available for all of your metal fabrication needs, including plasma cutting services. Read on to learn about plasma cutting vs laser cutting!

What is Laser Cutting?

Laser cutters use high powered, computer operated lasers combined with nitrogen, oxygen or compressed air—this technology allows these cutters to easily cut through a variety of materials and perform a wide variety of jobs. Laser cutting is a precise thermal cutting process, using a focused beam of light. This manufacturing process is best suited for applications that require tighter tolerances.

What is Plasma Cutting?

Plasma cutting is a low-cost cutting process that operates with high speed and precision. Compressed air and inert gasses are passed through a fine nozzle, creating electrically conductive ionized gas, also known as plasma. Plasma is the fourth state of matter, with solid, liquid, and gas being the first three.

Common materials that can be cut with a plasma torch include steel, stainless steel, aluminum, brass, and copper. Plasma cutting machines are often used in fabrication shops, automotive repair, and restoration, industrial construction, and more. Like a laser cutter, a plasma cutter cuts through metal by melting it.

Plasma Cutting vs Laser Cutting

- Laser cutting has a tighter tolerance so it has an advantage when it comes to performing intricate cutting tasks. Lasers are great for engraving details or cutting out small shapes from the metal, whereas plasma is better for more simple cuts.

- Plasma cutters can cut through thicker sheets of metal than lasers. In general, a plasma cutter can cut through metal up to 1.5 inches thick, whereas lasers can cut through metal up to one inch, depending on the kind of metal being cut.

- Plasma can only cut metal and other conductive materials, whereas lasers have been used to cut all kinds of materials including wood, plastic, glass, and other materials. This is due to the fact that the plasma cutter uses electrically conductive gas, rather than a focused beam of light.

- Lasers cannot cut highly reflective materials like copper, so plasma cutting is the best option. Plasma can cut through any conductive metal, regardless of its surface characteristics.

- Plasma cutting is more cost-effective than laser cutting. Lasers are typically more expensive to operate but can cut with more detail than plasma cutting.

Plasma Cutting in Phoenix

So, when it comes to plasma cutting vs laser cutting which cutting process is better? That depends entirely on your specific needs. The type of project, as well as the thickness of the material and level of detail needed, will definitely play a role in the one you choose. Plasma cutting is a smart choice for anyone working throughout the construction industry! Give our experts at Arizona Iron Supply a call if you are in the Phoenix area and need plasma cutting services. Be sure to also check out our extensive inventory online or stop by our warehouse for all your metal fabrication needs!

Image by Michal Jarmoluk from Pixabay